Aerial Vehicle Series

view products

Light Electric Vehicle

view products

Sustainability System

view products

Electric Vehicle

view products

Marine

view products

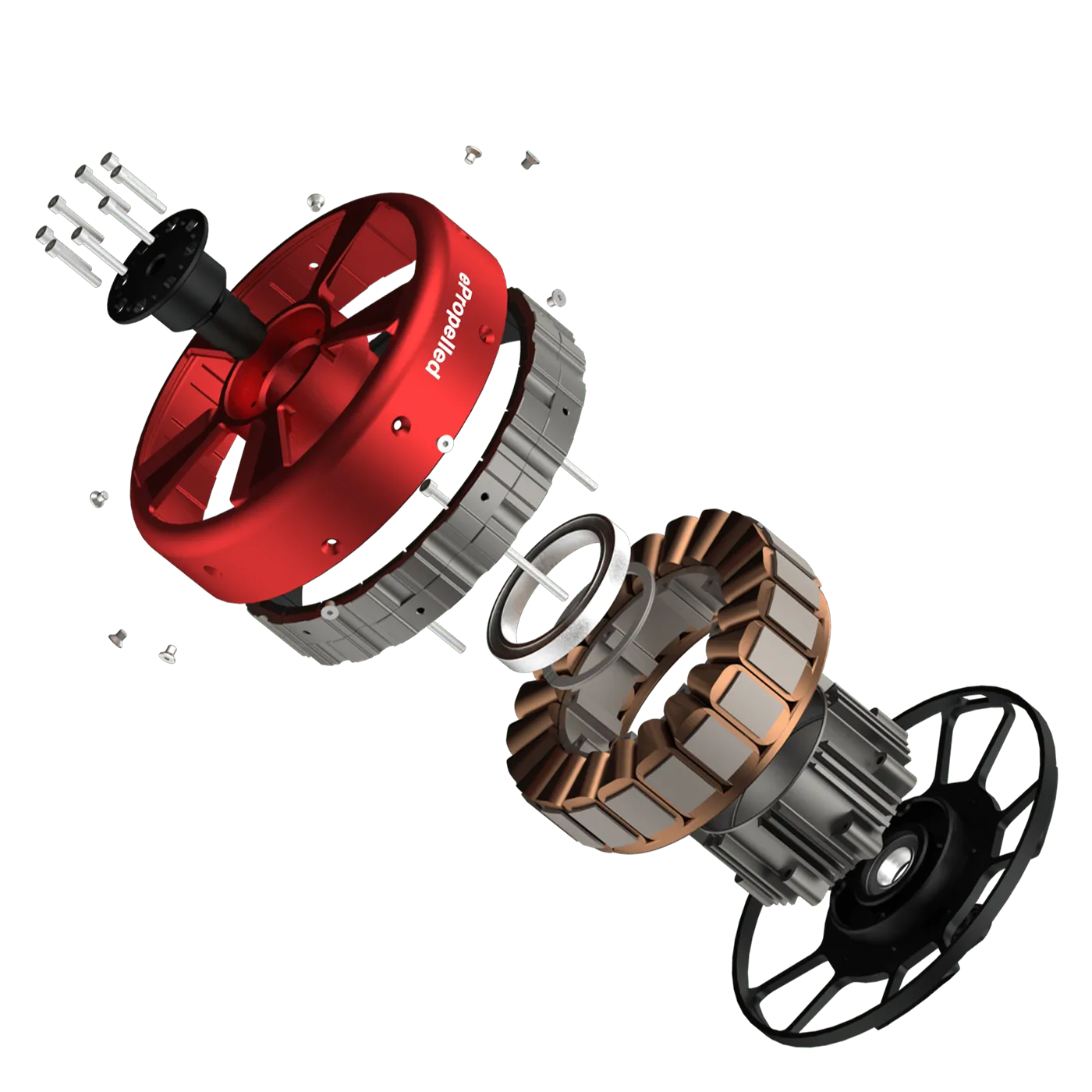

state of the art motors,

state of the art motors,  generators, and power management systems.

generators, and power management systems.